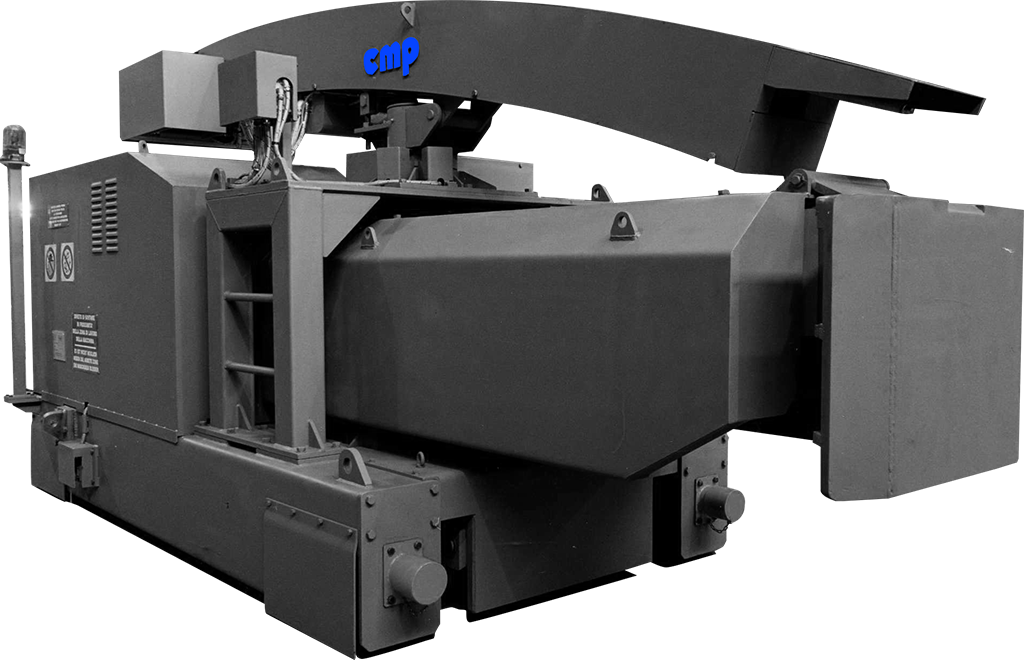

E.A.F. scarp

pusher and slag

door cleaning

machine

The market benchmarkt

The use of this remote controlled machine is aimed at providing a safe method of feeding scrap metal through the slagging door during the charging cycle and, subsequently, to the molten steel bath during the fusion cycle; it also makes it possible to guarantee constant removal of surplus slag from the slagging door.

Can be supplied with a manipulator for temperature measurement, sample taking and/or measurement of oxygen contents; can also be equipped with consumable lances for the injection of oxygen and carbon.

E.A.F. Scrap Pusher and slag door cleaning machine – driven cable reel solution - 200KN Pushing Force

E.A.F. Scrap Pusher and slag door cleaning machine – driven cable reel solution - 200KN Pushing Force

E.A.F. scrap pusher and slag door cleaning machine - forntal rail traveling - cable reel solution - 150kn pushing force

E.A.F. scrap pusher and slag door cleaning machine - forntal rail traveling - cable reel solution - 150kn pushing force

E.A.F. Scap Pusher and slag door cleaning robot - lateral rail traveling - cable chain solution - equipped with sampling and temp. manipulator

E.A.F. Scap Pusher and slag door cleaning robot - lateral rail traveling - cable chain solution - equipped with sampling and temp. manipulator

E.A.F. scrap pusher and slag door cleaning machine - frontal rail traveling - cable reel solution - 150kn pushing force

E.A.F. scrap pusher and slag door cleaning machine - frontal rail traveling - cable reel solution - 150kn pushing force

E.A.F. Scrap pusher and slag door cleaning machine – 150KN Pushing force – Frontal rail traveling – equipped with sampling and temp. manipulator

E.A.F. Scrap pusher and slag door cleaning machine – 150KN Pushing force – Frontal rail traveling – equipped with sampling and temp. manipulator